Targets - Work Center Manager

|

Targets is a collection of tools to help you manage, analyze and plan your daily production processes. Planning for longer lead time purchased items is best done through MRP. Click here to find out more about our Buckets program.

I found myself in an alarming situation. We had plenty of black wire in inventory. But when an order came in for a product requiring 18" black wire leads, there was none to be found. Apparently, it had all been cut up into 12" sections in anticipation of customer orders. You know, "maximizing our machine set up" and that sort of thing. Unfortunately, our customers abruptly began ordering a version of the product with longer wires. Ever happen to you? Simple KanBan techniques can synchronize your production flow to demand. Targets can help you implement KanBan easily. Another problem I faced was the number of inventory errors in our system. I suspected that production was not being reported accurately. Targets includes the following tools to help smooth and control your production. |

|---|---|

|

Digital KanBan.KanBan is a great way to control and expedite your production. And Target's Kanban tools eliminates many of the problems that cause traditional kanban to fail. Targets includes the ability to implement and manage digital KanBan easily. Click to learn more about KanBan in general. Click to see how easily Targets can implement KanBan for you.

|

|---|---|

|

Intelligent Production Reporting.Garbage in = Garbage out. If the production you report is wrong, finished goods as well as component inventories quickly become questionable. If you're a manufacturer or if you convert components into inventory in any way, conversion reporting is always a suspect in inventory errors. Taking advantage of Target's Production Reporting and Analyzing tools will help eliminate errors. All reported production is recorded and analyzed. Questionable conditions are brought to the user's attention for confirmation before being recorded. This data may also be sent to another software program to avoid duplicate data entry. Click here for more information about sending this information to another program. Click to find out more about Target's production reporting.

|

|

Prioritize your immediate requirements.Target can consider your inventories and current orders to build a unique "Crash & Burn" report. In seconds, you will know what must happen and when it needs to happen. Click to find out more. |

|

Minimize Production Reporting errors starting at the top.Making accurate job assignments is the first step in eliminating reported production errors. Targets makes it easy to create a work order and print out a pre-filled production report form along with other documents you choose. Many errors can be caught when proper information is available. Information is pre-printed on the form. Along with a full part description, standard pack, and production rates per hour. Click to find out more about making work assignments. |

|

Minimize Production Reporting errors by review and analysis. And get a productivity boost for free!Once your production data is entered into Targets, it is analyzed for suspicious entries. Employees who report more than or less than the expected number of hours. Part numbers that don't exist, or product you don't need. Even production rates that fall outside of your expected range of rates. You know just what to look into. Once you're satisfied the reported values are correct, finish processing the entries.

Ok, here's your free tip: Implement this tip and save more than the cost of the Targets program. Click to find out more. |

|

Keeping ahead of manpower requirementsSometimes it's difficult to tell if you're catching up or falling behind. Do you need over-time? Or is it time for optional Fridays? Targets has the tools you need to watch your manpower requirements. Workloads are charted so you can easily know how you're doing in general. You can also examine work loads by each individual work center. Click to find out more. |

|

Production rate calculator toolEasily calculate the reported production rates for a production item. If you wish, you can set a special date range, or filter to include or exclude a specific employee, require a minimal number of reported hours, or quantities. Then in a flash get the actual production rate for your search criteria. Click to find out more. |

We sold roughly 800 different products in any month and had to be able to ship on very short notice. We ran an MRP system, which was excellent for forecasting demand especially on long lead time items, but we needed something that reacted quickly to changing customer demands in our final assembly areas. Kan-Ban seemed like an excellent choice. Nothing reacts quicker and if you've never tried it, you should. But how do you manage all those Kan Ban cards? And where do you place all of those card holders? And who changes the Kan Ban card holders every time the planned maximum is changed?

What I wanted...

Have you ever tried using Kan-Ban for scheduling? It really works. The problem I ran into was those darn cards. Where can you put them? I've never had the luxury of having adequate space for all those cards. Then, how do you manage the frequent changes in the number of pull signals you permit? And of course, you have to start cycle counting cards in addition to inventory. They do occasionally go home in someone's pocket!

Kan-Ban is especially interesting if you believe that scheduling is best handled by the actual work center making the parts. Who knows better what is involved in changing production over from one item to another? And the work center team is the expert in watching inventory consumption. Or they should be.

Targets ™ to the rescue

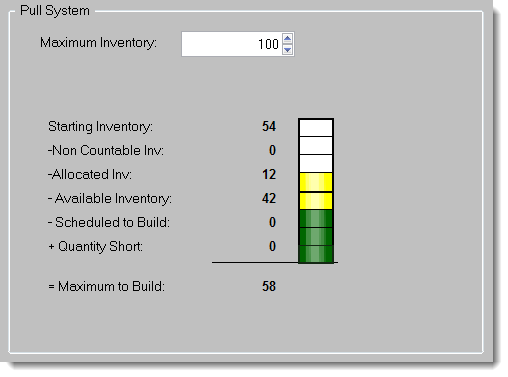

WorkCenter is an easy to use program that allows you to set maximum inventories based on your anticipated sales and demand variance. Your production team can view all of the parts assigned to their work center along with a traditional kan-ban style "thermometer" showing the relative inventory situation. If you have the right people in these key positions, the work centers can use this program to schedule themselves and you'll never have to worry that they are over-building.

WorkCenter Planner enables your production centers to be self-scheduling and they will react instantly to changing customer demand. If you build or assemble multiple products for customers who's order seem to change with the wind, WorkCenter will:

- Improve your line fill by prioritizing production, without constant planning and re-planning.

- Eliminate stock outs and over-inventory situations by controlling inventory build with acutal customer demand.

- Free your time by enabling you to delegate production scheduling decisions to the factory floor without risk.

- Guide your manpower requirements by tracking the number of production hours available by each work center.

- Alert you to problems if a work center builds beyond your allowable limits.

Interested? Find out more.

Click